Contents

Slump test of concrete

Before pouring freshly mixed concrete, a standard operation called a concrete slump test is carried out on the material to assess the consistency of the concrete. The test is very easy to do, and it is a wonderful and speedy tool for determining whether or not various batches of the same concrete are consistent with one another.

Before being included into a building project, freshly mixed concrete that is about to undergo the pouring process has to fulfil specific requirements before it can be employed. The consistency of a batch of concrete is evaluated using a test known as a slump test in order to determine how readily the concrete will flow. The test not only determines whether or not there is consistency across batches, but it also reveals any flaws that may exist within a mix. This provides the operator with the opportunity to modify the mix before it is poured at the place.

If you measure the overall “slump” of the concrete, you will be able to determine whether or not the ratio of water to cement is too high, as well as whether or not a mix will have a high level of workability.

Why is it necessary to do a slump test of concrete?

The primary goal of carrying out the assessment is to confirm that individual batches of concrete will always have the same level of quality and hardness. When more water is added to a mixture, the resulting concrete will be of worse quality. If required a concrete mixture that is easier to work with and flows better (which will result in a larger slump), it needs to increase the amount of cement in the mixture to make sure it still gets the desired level of strength.

The Basic Idea Behind the Slump Test

The result of the slump test is a measurement of how concrete behaves when compressed into the shape of an inverted cone when subjected to the force of gravity. It does this by measuring the consistency of the concrete as well as its level of wetness, which then provides a notion of the mix’s condition in terms of its workability.

Importance as well as Application

Using this procedure, the consistency of newly mixed Portland concrete may be determined. The ease with which concrete may be compacted and laid is one indicator of the workability of concrete, which can be largely determined by this test. For purposes of quality control, this test is carried out both in the laboratory and out in the field.

Slump test procedure

- A frustum of a cone with a height of 300 millimetres or 12 inches is used as the mould for the concrete slump test. The diameter of the base is 200 millimetres (8 inches), while the top has a smaller hole that is 100 millimetres (4 in).

- After that, the container is filled with concrete in three levels, and its workability is assessed. The base is then positioned on a level and smooth surface.

- Each layer is temped a total of 25 times using a steel rod with a standard diameter of 16 millimetres (or 5/8 inches) and a rounded tip.

- The top surface of the mould is struck off (levelled with the top aperture of the mould) using screening and a rolling action with the temping rod after it has been completely filled with concrete. This is done after the mould has been completely filled.

- Handles or foot rests that are brazed to the mould are two options for ensuring that the mould is held securely against its base during the whole of the operation. This is necessary to ensure that the mould does not move as a result of the pouring of concrete.

- As soon as the filling process is finished and the concrete is levelled, the cone is hoisted vertically in a gradual and careful manner. At this point, unsupported concrete will begin to sink.

- Slump is described as a decrease in the height of the slumped concrete’s centre.

- The measurement of the slump is accomplished by positioning the cone in such a way that it is immediately next to the region of slumped concrete. Next, the temping rod is positioned above the cone in such a way that it will also pass over the area of depressed concrete.

- A scale is used to record the height of the mould before and after the concrete is poured into it. (normally measured to the nearest five millimetres or one-quarter of an inch.

Limitations Of Slump Test

- It should not be relied on for lean mixes. When there is not enough moisture in the mixture, a true slump may readily transform into shear or collapse. It is possible to find a large level of variation within a single sample of lean mix, which might make it very difficult to establish the precise outcome.

- though various kinds of aggregates might have quite varying workabilities, the slump measurement can be the same for each. It is to be noted that slump is not a measurement of how easily the material may be compacted. The slump only happens when the concrete is under its own weight. It doesn’t show how the concrete would act when vibrated, finished, pumped, or put through a tremie.

- Multiple shapes may provide the same result for a specimen, which can make determining the proper result difficult. If shear slump develops, it is possible that the following test will show real slump.

- Because it demonstrates no slumps, it is unable to discriminate between the workability of stiff mixtures. When the mixtures are dry, it is impossible to distinguish one from another, regardless of their respective workabilities.

- It is not appropriate for use in concrete that has aggregate larger than 40 millimetres in size.

Read more: Fly Ash Bricks: A Sustainable Alternative to Concrete

Precaution during test

- It is important to thoroughly clean and dry the inside surface of the mould before proceeding.

- It is important that the base plate or surface not be subject to any vibrations or startling.

- This test is carried out very immediately after the sample that was completed approximately 2 minutes later.

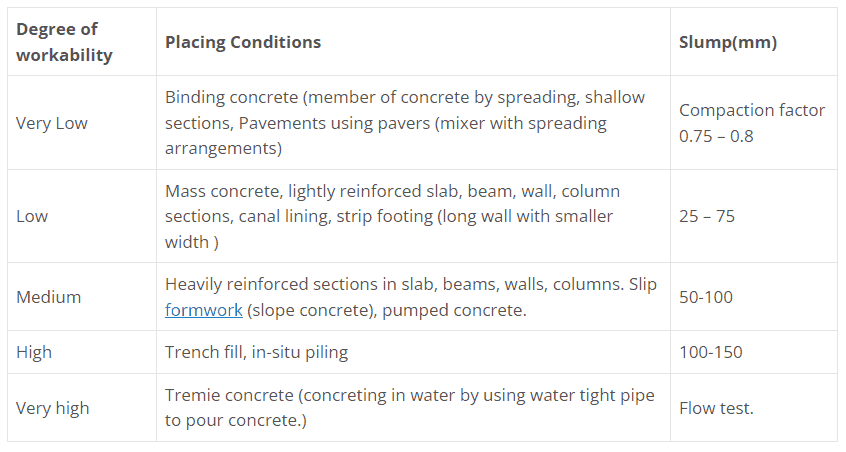

Interpretation of results

Shape of concrete slump

- True Slump: The term “true slump” refers to the gradual descent of the concrete mass in all directions without the material falling apart. The ideal slump would look something like this.

- Collapse Slump: The presence of collapse slump shows that the concrete mix has an excessive amount of water, and the mix is considered to be harsh and lean.

- Shear Slump: This particular form of slump is identical to the shear collapse of the soil. This is an indicator that the concrete mix elements are not cohesive enough with each other. After that, a new sample is collected, and the procedure is carried out once again.

Read more: The Workability of Concrete: Strength And Durability Of Concrete

Slump Cone is influenced by the following factors

- The proportion of water to cement in concrete.

- the quality of the coarse and fine aggregates, including their form, the amount of moisture they contain, the texture they have, and their grading.

- The addition of a plasticizer and a superplasticizer admixture, as well as the order in which they are mixed.

- The amount of air that is contained inside concrete as well as its void ratio.

- The length of time for the test after the concrete has been mixed.

Conclusion

A slump test is a quick and easy way to determine the workability of concrete. The test is performed by filling a cone-shaped mold with fresh concrete, then lifting the mold and allowing the concrete to slump. The amount of slump is then measured and recorded.

The slump test is an important tool for quality control, as it can help to ensure that the concrete is of the proper consistency. Workable concrete is important for a variety of construction applications, as it helps to ensure that the concrete will flow properly and evenly into forms and molds.

The slump test is a relatively simple test to perform, and it can be a valuable tool for quality control in concrete construction.