Contents

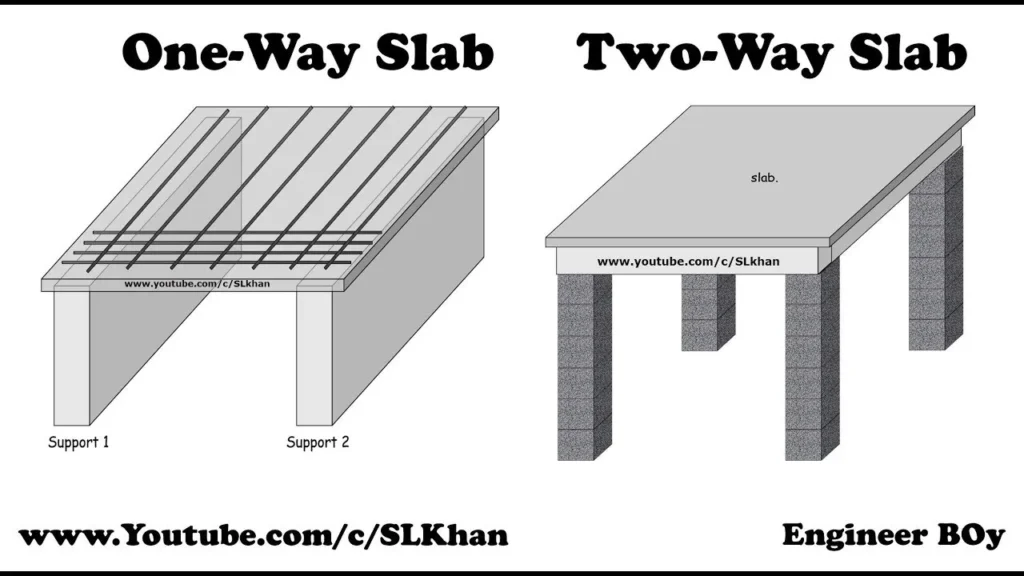

What is one way slab

A certain kind of slab known as the one way slab is characterised by having a ratio of the longer span to the shorter span that is more than two. This gives the one way slab its name.

Using some basic math, we can write this as: (Longer Span / Shorter Span)≥ 2

To put it another way, the load is transmitted in only one direction across the one-way slab because the beams that support it are arranged in such a manner.

The distribution reinforcement is installed in the one-way slab’s lengthier span, while the primary reinforcement is placed in the shorter span of the slab.

One way slab design

Steps to design one way slab

- Determines the kind of slab being used.

- Determine the hmin value and sum it up to the next greater multiple of 10mm.

- The minimum for rooms must not be lower than 110 millimetres.

- The thickness of sunshades must be at least 75 millimetres.

- Determine the amount of the slab’s dead load that is bearing on it.

- Dead Load is equal to the load multiplied by the width of one metre.

- Figure out the live load that is being supplied by the slab.

- Live load is defined as the load multiplied by the width of one metre.

- Calculate the total factored load per unit strip in kilonewtons per metre.

- Determine moments.

Determine effective depth.

d = h – (20 + (½)db) db = 10, 13, and 15 are the most commonalities.

- Make sure that the d is more than or equal to dmin.

- Perform the appropriate calculations for a width of 1 metre.

- Determine the minimum/distribution/temperature, as well as the steel shrinkage.

- In the Analysis and Design of Slabs, we will need to determine the diameter of the primary steel beams as well as their spacing.

- Make sure that the minimum and maximum spacing requirements are met.

- In most cases, one smin is almost equivalent to ninety millimetres.

- If the space is narrower than the minimum, the diameter of the bar should be increased.

- For continuous slabs, the positive steel should be shortened or bent up. Examine the quantity of negative steel that is already available. Needs to bring in the remaining quantity of steel.

- Figure out how many distribution bars there are. Determine its diameter as well as its spacing.

- Verify that the shear of the slab is correct.

- Detailing should be carried out, and the results should be shown on the drawings.

- Make a schedule for the bending of bars based on the relevant parameters.

Read more: Ways to get tradingview premium for free

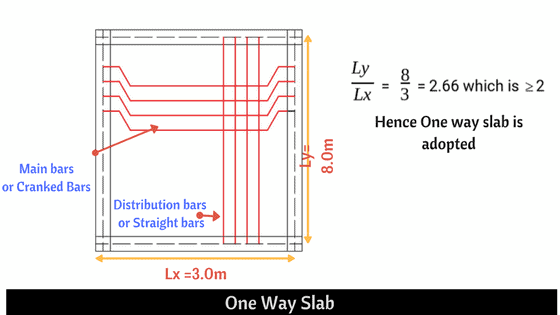

One way slab reinforcement details

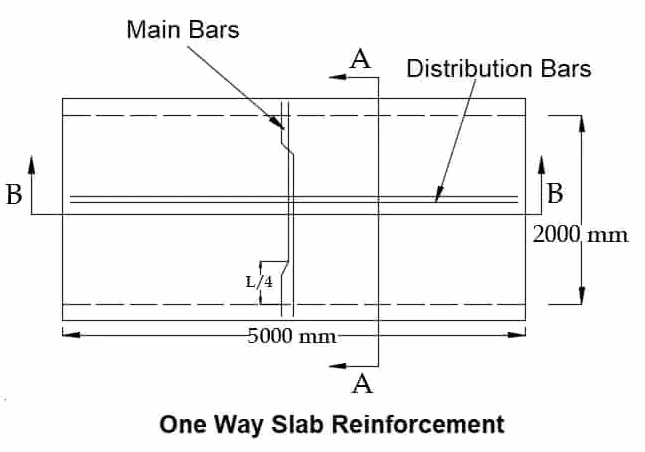

In the one-way slab, on the smaller side, the primary bars are provided, as indicated in the image that is shown above. Even if the distribution bars are on the bigger side, they are nonetheless supplied. The distribution bars, on the other hand, are on the longer side.

Read more: Shear Wall- How to construct, Types, Advantages & Disadvantages

The bigger side of a one-way slab carries the most significant weight since one side is higher than the other, hence providing primary reinforcement in comparison to the load-bearing side will be sufficient.

The primary reinforcing bar is placed perpendicular to the bigger side or parallel to the shorter direction to give suitable support. On the bigger side, distribution bars are supplied, however, they will not assist in bearing any weight.

The bigger span in the above slab, 5000, divided by the shorter span, 2000, is 2.5, which is more than 2.

Therefore, it is a slab that only goes in one direction. As can be seen, the main bar, which is the bar with the bigger diameter, is supplied at the smaller side.

Calculation of One-Way Slab Reinforcement

The primary reinforcement for a one-way slab is calculated using a formula (in limit state design) that is found by comparing compressive and tensile forces.

The primary reinforcement for a one-way slab is calculated using a formula (in limit state design) that is found by comparing compressive and tensile forces.Ast = 0.5 Fck/Fu[1-√1-2.6Mu/Fck.b.d]b.d

The distribution steel is calculated as follows: For mild steel, 0.15 percent Ag is used. Tor steel has 0.12 percent Ag. Where Ast is the tensioned steel's area. Steel's ultimate strength is called Fu. Mu is an abbreviation for "ultimate moment of resistance." b = The slab section's width. d is the slab section's depth. The gross area of the section is denoted by the abbreviation Ag.

Conclusion

A one way slab is one that has beams on just two opposing sides. This type of slab is suitable for spans up to 6 m. One way slabs are typically used for floors in residences and office buildings. The main advantage of a one way slab is that it is more economical than a two-way slab.

- If four sides are supported, the ratio of longer to shorter sides is calculated; if it is larger than 2, a one-way slab is built.

- If it’s only supported on two sides, it’ll always be a one-way slab.

- Now, the major reinforcement must be provided exclusively in the shorter direction, as determined by the strength and deflection criteria.