Contents

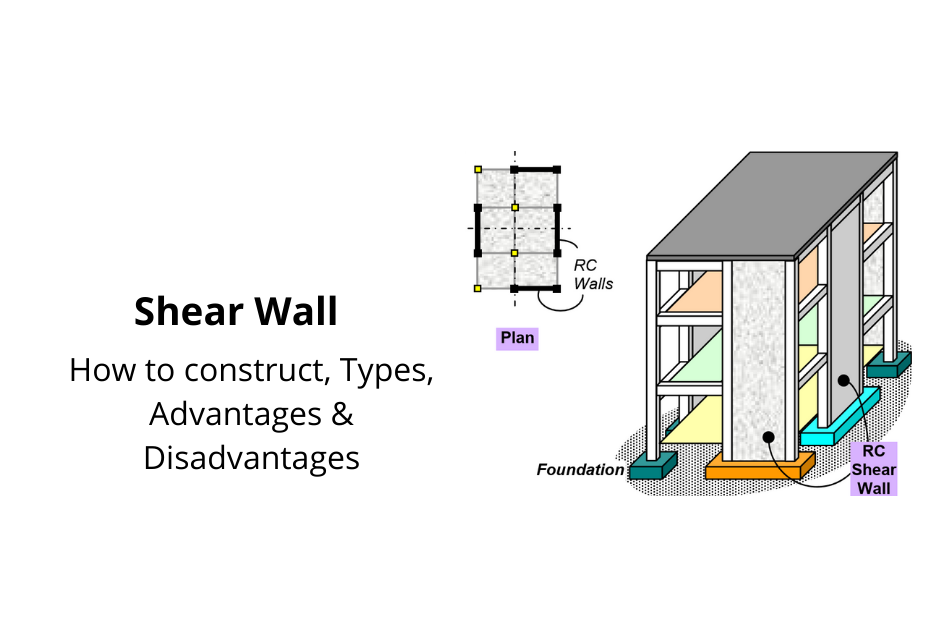

What is a Shear Wall?

Shear walls are often used in high-rise structures because of their resistance to lateral wind forces as well as seismic forces. Shear walls are also used in certain other types of structures. When it comes to constructions made out of reinforced concrete and steel frames, the impacts of wind forces become more significant as the height of the building rises. Limits on horizontal movement, often known as sway, are typically imposed by codes of practise.

Shear wall definition

A shear wall is a structural panel that can resist lateral forces acting on it. Shear walls are particularly important in large, or high-rise buildings, or buildings in areas of high wind and seismic activity.

Shear Wall Design

Consider a wooden square with four corners; in principle, this represents two columns and two beams. This is the simplest method to get a grasp on how shear wall design work, even if it may need a formal degree in structural engineering to fully comprehend the physics behind shear wall construction. Because any force that is placed on the top beam is passed via the columns and down to the base of the square, this framework is able to withstand weight from above, also known as compression.

However, excessive amount of pressure is put on its sides, sometimes known as a lateral force, the square would twist and collapse on itself unless it is braced by supports. Shear wall construction are equipped with these bracing and are constructed in such a way that they are not able to collapse in on themselves. In return, they ensure that the home will not be harmed by the wind.

Shear wall design does, however, provide a challenge to the architectural design process because of the support they give. Regardless of whether the support against lateral stresses is provided by the sheathing covering the frame or by other bracing included within it, the entire area of the shear wall design that any windows or doors take up must be restricted, and in certain applications, they simply cannot be used at all.

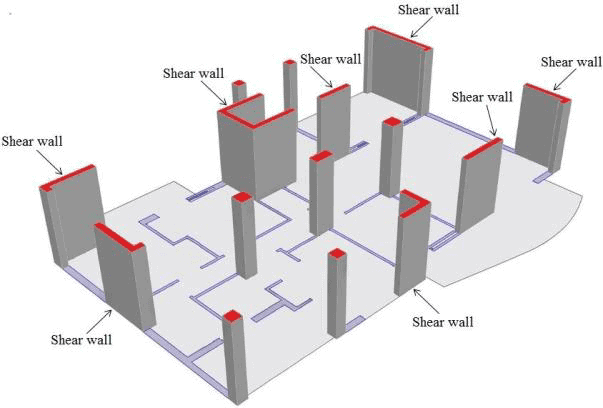

What type of structures requires shear wall construction?

Internal shear wall construction are often incorporated in bigger homes and high multi-storey structures that are susceptible to lateral winds and seismic stresses. However, almost all lifts have shear walls on atleast two sides. The need for an interior shear wall system and a lateral force resisting system increases in proportion to the height of the structure.

Shear wall construction

Shear walls should be positioned in the middle of each half of a structure as a general rule. This is the ideal spot for a shear wall construction in high-rise buildings as well as dwellings that are required to have shear walls. After that, shear walls have to be constructed in a symmetrical manner around the centre axis of the structure.

To put it another way, if there is a shear wall on its north side, then there must also be one on its south side that is an excellent parallel. On the other side of the central axis, a building will have a similar shear wall, which is the Northwest corner, if there is a shear wall located at the Northeast corner of the structure.

Installation of shear walls

A home that has shear walls installed successfully may be achieved by adhering to a few basic criteria. Sheathing, which may be either plywood or OSB, is attached to the frames of the majority of homes during this procedure.

Verify that the OSB or plywood has a panel stamp indicating that it is rated as sheathing and that the DOC product standard satisfies the requirements of the building codes. For plywood, use PS1, and for OSB, PS2 should be used.

Choose panels with lengths that are sufficient for your specific sheathing job (they come in lengths of up to 12 feet). The greater the length of the panel, the less blocking is necessary.

An axis of strength runs down the length of each panel. The installation of the panels horizontally may give higher resistance to wind, but the installation of the panels vertically involves less effort. However, there are certain authority, such as the Engineered Wood Association, who say that the efficacy of horizontal and vertical installations are same.

Nails should be used to secure the sheathing to the frame. The architect, designer, or engineer will provide blueprints that detail their dimensions and the distance between them.

At last, all of the sheathing must be fastened to the foundation walls using metal connectors to provide a secure connection (these will also be specified in the plans).

Advantages of Shear Walls

- A building has increased strength, stability, and stiffness due to the addition of these walls.

- Lessen the building’s tendency to lean laterally.

- Simple in its construction and straightforward in its use on the site

- Walls that are thinner, leading to a reduction in weight.

- Successful in reducing the amount of damage caused by earthquakes to both structural and non-structural components.

- efficient in terms of cost.

- A shorter construction time

- the best overall performance

Disadvantages of Shear Walls

- During the process of concreting the shear wall using the formwork, supervision is necessary to ensure appropriate compaction. If certain precautions are not followed, the vacuum will be remained in the shear wall. As a consequence of this, the strength of the shear wall is reduced.

- This kind of wall does not have any windows of any kind.

- The construction of this kind of wall demands labourers with certain skills.

- Reinforcement can be placed in the shear wall design with a great deal of difficulty. Reinforcement is particularly difficult to put, especially in c-type shear walls, which are particularly challenging.

- They give off the impression of being quite fragile.

- Additionally, the buckling of the web plates is accompanied by the sound of loud hammering.

- It does not have a high ability to dissipate energy.

- Also, demands huge moment connections.

Types of shear walls

- Wooden framework consisting of vertical studs and sheathing- In the construction of buildings in the United States, this kind of shear wall is the most typical. Sheathing, often consisting of plywood or oriented strand board, is applied over the top of the framing since a wooden structure that just consists of vertical studs is susceptible to deformation and collapse (OSB). This ensures that it will continue to maintain its rigidity even when subjected to lateral pressure.

- Steel- These shear walls are often made of steel sheets rather than plywood when used to bigger structures.

- Diagonal braces- A diagonal brace placed inside of a frame, whether it be constructed of steel or another material, gives an additional amount of support.

- Moment frames- You may install a window or door in these rectilinear, stiff constructions, which serve the same purpose as shear walls but also allow for the installation of windows and doors. This is an expensive choice because to the high cost of the materials and the effort required to construct them.

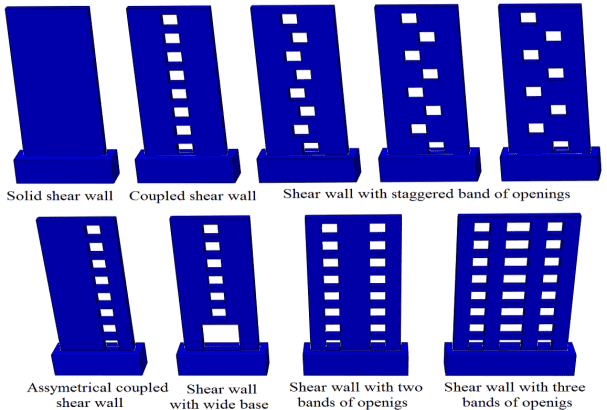

Shapes of shear walls

Although the majority of shear wall design take the form of straightforward rectangular planes, there are a number of other configurations that may make these walls even more efficient at withstanding the forces of wind and earthquakes.

- Core walls are box-shaped shear walls that create a square or rectangle around a central core, which often holds a building’s elevators and other mechanical systems.

- Walls in the form of a C protrude somewhat beyond the main plane at both of their ends.

- Walls in the form of a L protrude farther from one end of the plane than the other.

- The letters of the alphabet continue with the T-, U-, and W- arrangements, as well as additional combinations designated after the letters they are most similar to.

The structural engineer will assess which configuration is the most appropriate for the given circumstances, some being better at absorbing the shock of seismic activity while others being more adapted to withstand the force of strong winds.

The following categories of shear walls are distinguished by the kind of material that they are constructed from.

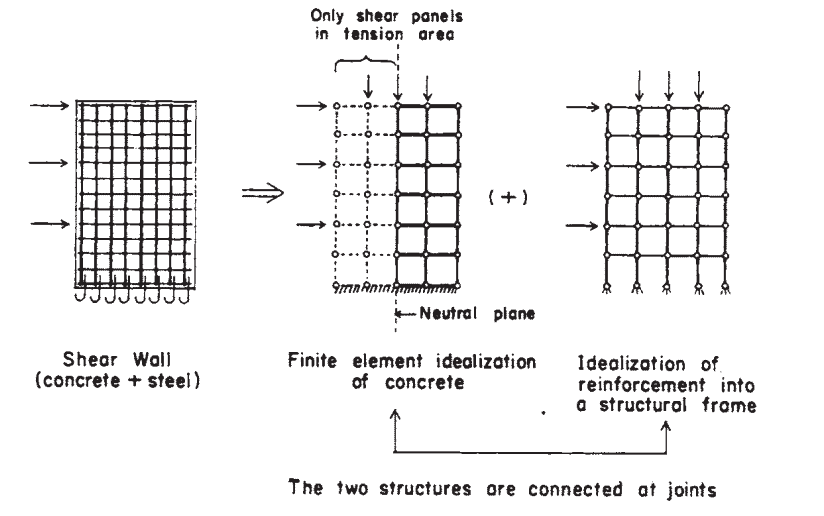

Reinforced Concrete Shear Wall or RC Shear Wall design

Shear walls made of RCC are among the most common types of shear walls used in residential construction. Both the horizontal and the vertical directions are covered by the reinforcement. On the other hand, at the end of each wall, there are strongly fastened and closely spaced bars.

The wall thickness of an RC shear wall may vary based on a variety of parameters, including the energy absorption needs of the structure, how old is the structure, the number of storeys in the built structure, and so on. In most cases, the installation of shear walls continues uninterrupted over the whole of the building’s height. However, there are situations in which it is not allowed, such as if there is an entry to a building or a parking area.

Concrete Block Shear Wall design

Shear walls made of concrete blocks are typically created utilising hollow concrete blocks in combination with reinforcing bars. It is common practise to make use of reinforcement while attempting to optimise the impact that concrete block masonry has against seismic loads. Both vertically and horizontally, the reinforcement bars are laid out in a pattern that allows them to pass through the gaps between the concrete blocks.

Following the installation of the bars in the concrete block masonry, new concrete grout is put into the voids between the blocks and then given time to cure. The gravitational loads as well as the lateral loads may be supported by these types of walls. Therefore, they are capable of working both as load bearing walls and shear walls.

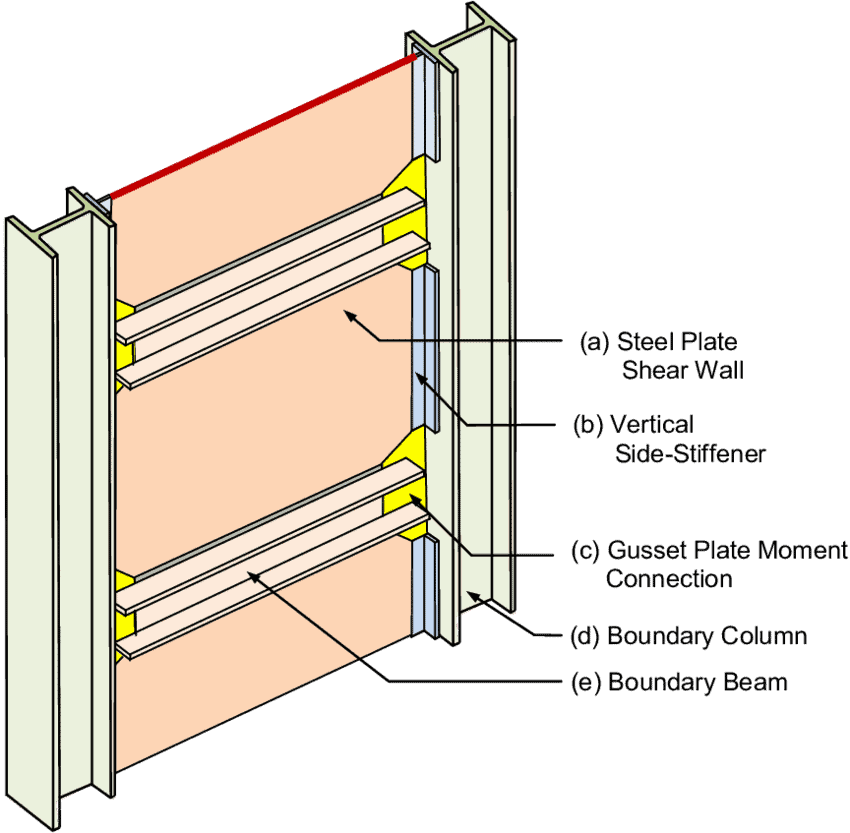

Steel Shear Wall design

The components of a steel shear wall are as follows:

- a boundary column,

- a horizontal floor beam, and

- a steel plate wall.

Steel shear walls behave more like plate girders in terms of their function. Plate girders are characterised by their use of steel plate walls as the web. When compared to the wall thickness of concrete shear walls, the structural wall thickness that may be used with steel shear walls can be reduced.

Plywood Shear Wall design

Shear walls constructed from plywood are a conventional form of wall that are also referred to as timber shear walls. Sheets of plywood and studs make up its constituent parts. Shear forces are transmitted via plywood sheets, whereas tension and compression are resisted by studs. Plywood shear walls are being rethought and modified in light of recent developments in technology.

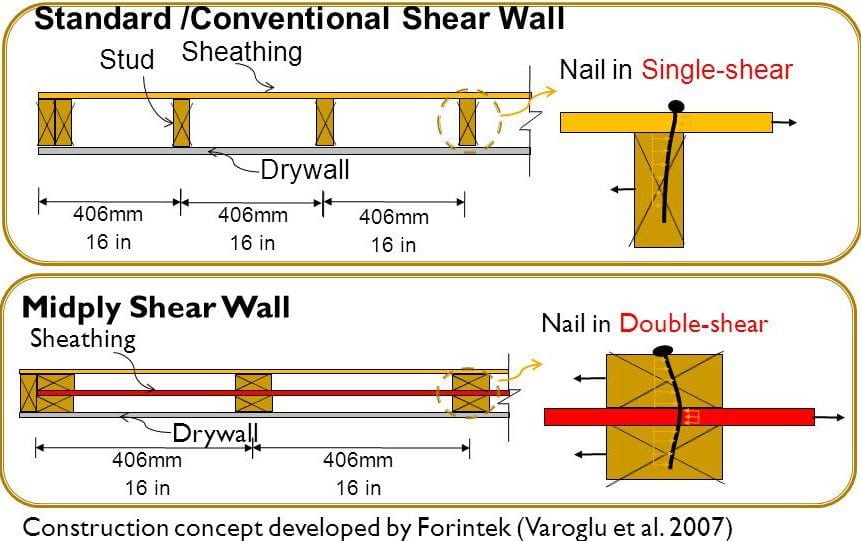

Mid-Ply Shear Wall design

The traditional plywood shear wall has been upgraded to an enhanced form known as the mid-ply shear wall. The mid-ply and the outer plywood sheets are joined together by studs. In this instance, the Studs are rotated by 90 degrees in relation to the plywood shear walls. The issues that are created by conventional shear walls are eliminated by this wall and have a better lateral load bearing capability than normal shear walls.

References

- EVALUATION OF RESPONSE MODIFICATION FACTOR FOR SHEAR WALL WITH OPENINGS IN MULTI-STOREY BUILDINGS – Scientific Figure on ResearchGate. Available from: https://www.researchgate.net/figure/3-D-view-of-a-building-with-different-types-of-shear-walls_fig2_356361617 [accessed 29 May, 2022]

- Development of a high-performance steel plate shear wall system – Scientific Figure on ResearchGate. Available from: https://www.researchgate.net/figure/The-main-components-of-the-new-high-performance-steel-plate-shear-wall-system-discussed_fig1_309519244 [accessed 29 May, 2022]

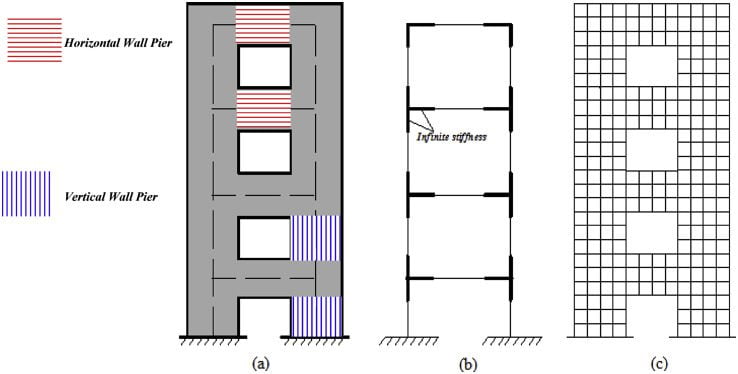

- https://doi.org/10.1016/B978-0-08-011692-1.50023-7

- https://doi.org/10.1016/j.compositesb.2016.06.063